We manufacture and supply coating plant and other process jigs, both standard and bespoke.

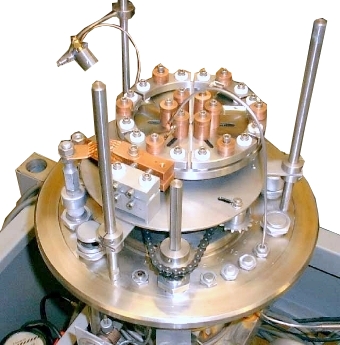

AVE 6 Position Rotating Source

Designed and manufactured by Applied Vacuum Engineering, this jig can be retro-fitted to most small coating plant, for example the BOC Edwards 306 series coating plant. It is supplied complete with a right angled rotary drive and drive chain.

In operation the jig will sequentially evaporate up to six different materials from a variety of sources; filaments, boats, baskets or small crucibles. The design allows for different size sources to be used and the source length can be from 30-60mm total length. LT power can be up to 20V 60A. Each source is shielded from all other sources. The whole jig is easily stripped for cleaning, and the shields are removable as a single SS fabrication with one bolt. Height within the process chamber is adjustable.

Materials of construction (except for the spring mechanisms) are OFHC copper, SS and ceramic.

The jig is also available as a co-evaporation source, so that two materials can be simultaneously evaporated. Up to three different compounds can be produced with this model. Two power supplies are needed for the co-evaporation version.

Rotary Planetary Substrate Jig

Shown is a system designed and developed for a special 20" coating plant. The jig is designed to give both height and angle adjustments on the planets. The planets counter-rotate to give optimum coverage of the required coating.